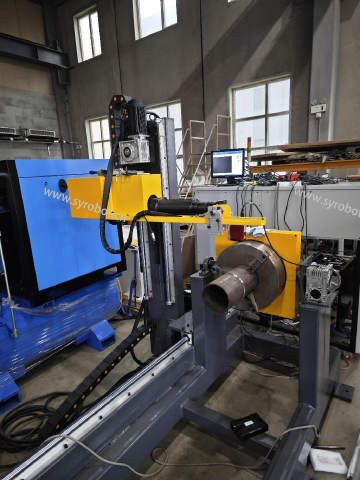

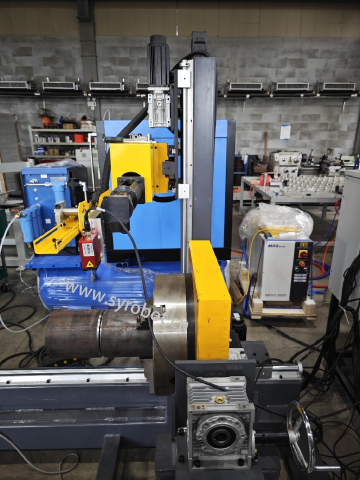

Second generation welding machine

一、Products

High-quality welded joints: TIG welding uses inert gases (e.g. argon) as a shielding gas to form a stable welding atmosphere that effectively prevents the ingress of impurities such as oxygen and nitrogen, thus avoiding oxidation and contamination of the weld area. This protective environment ensures a high quality weld, free of porosity, slag and cracks.

Suitable for a wide range of materials: Argon arc welding is suitable for a wide range of metal materials, such as stainless steel, alloy steel, copper, aluminum, etc., making it widely adaptable when it comes to pipeline connections and accessory welding of different materials.

Welding of pipe elbows and flanges: Thanks to its precision and controllability, TIG welding is particularly suitable for welding pipe elbows and flanges. Welding of pipe elbows requires consideration of angles and curves, while welding of flanges needs to ensure complete sealing of the connection. TIG welding is able to provide a high level of weld quality and reliability in these situations.

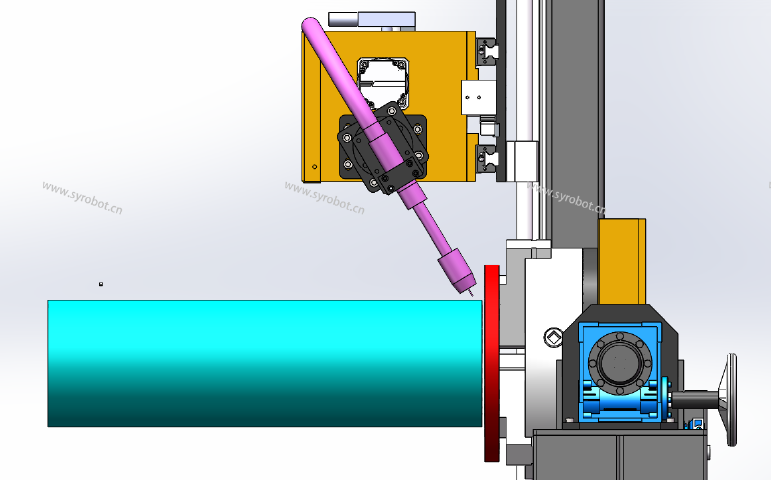

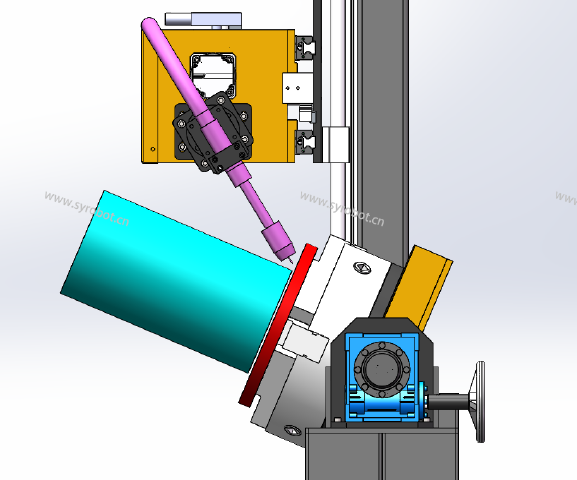

Angle Adjustability: Tig welding equipment often features angle adjustability, which is useful in situations where welding needs to be done at different angles. Whether welding horizontally, vertically or at an angle, the welding machine tig welding can provide accurate and stable welding results.

Environmental protection and energy saving: the argon arc welding process does not produce harmful fumes and exhaust gases, and energy consumption is relatively low. This makes the argon arc welding in the environmental awareness is constantly improving today favored.

In short, the welding specialized machine argon arc welding in the field of pipeline connection and accessory welding to show its unique advantages, including high-quality welding, multi-material applicability, applicable to a variety of angles of flexibility, and friendly to the environment. Whether in the petrochemical, energy, pharmaceutical or food processing industries, argon arc welding provides critical support for the safety and reliability of piping systems.

二、Applicable workpieces

Pipe specifications: diameter DN50-DN400, weld position ≤ 1500mm, wall thickness ≥ 3mm Note: (pipe length > 1000mm optional lifting bracket)

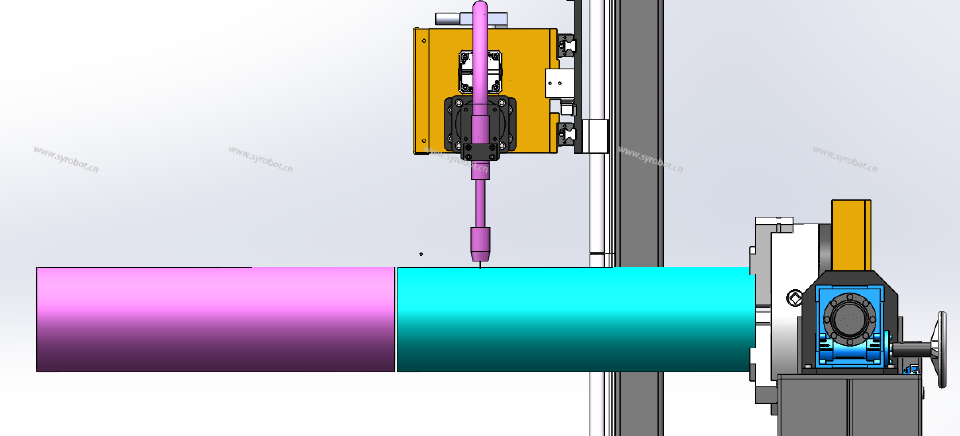

1-Pipeline + Pipeline:

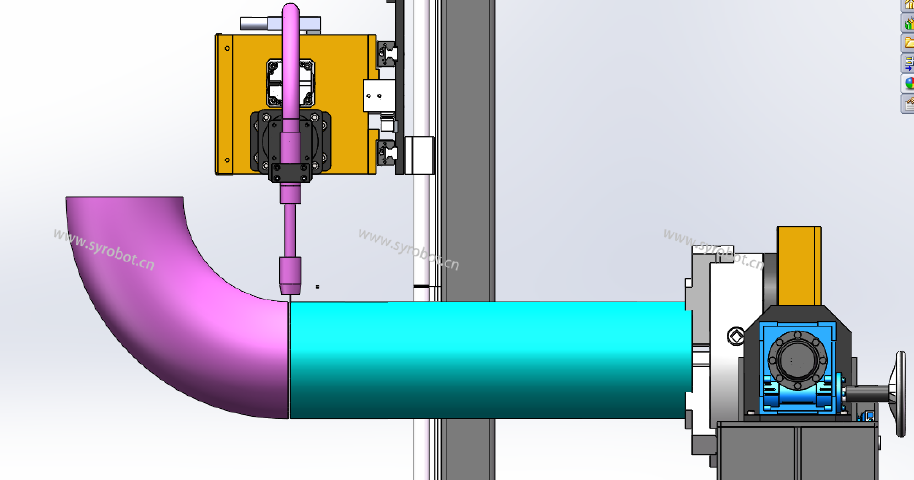

2-Pipe + Elbow:

3-Pipe + Flange:

4-Pipe + Flange:

三、Equipment Characteristics

1.Upgraded to ethercat bus control of motors, anti-interference

2.Welding position memory function, can be directly recalled next time

3.Welding process single function, a selection can set the welding speed, welding current, welding voltage, etc.

4.Welding process pause function, pause automatically back after the precise continue welding

5.High and low tracking function during welding (not available for pipes + flat flanges)