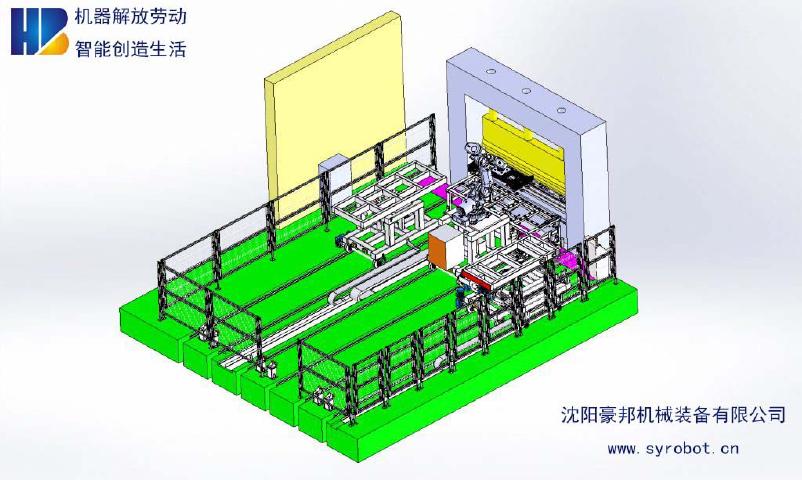

Robot loading and unloading (sheet bending)

Brief Description Of The Equipment

Used for bending and unloading of sheet material in the container industry.

Scope Of Application

Applicable plate length: 2~3.4m (can be customized)

Equipment Operation Process

- Preparation: turn on the machine and detect the raw material carriage running to the designated position.

- Workpiece alignment and positioning: the robot grabs the workpiece from the raw material carriage and carries it to the alignment platform for positioning and then sends it to the press.

- Press primary bending; the press bends the workpiece on one side.

- Rotating platform; robot picks up the workpiece for one-sided bending and rotates it 180° on the rotating platform.

- Press secondary bending; robot grabs the workpiece to the centering platform for secondary bending.

- Finished product unloading: robot grabs the workpiece to the finished product material car, manual unloading.

Equipment Features

- Reasonable positioning alignment to ensure the size after bending.

- Robot handling to achieve flexible automation.

3D Design Drawing Of The Equipment