Vertical plate welding machine

一、Equipment Introduction

This special machine is mainly composed of five parts; by manually placing the plate into the designated position, press the start button on the console to start welding; the equipment realizes the automatic loading and unloading of the plate, improves the welding efficiency and welding quality of the product; and reduces the labor intensity of the workers;

二、Equipment Characteristics

✅ Precision Welding: Designed for internal and external joining of plates and sheets, this machine offers high precision welding capabilities. It ensures accurate weld seams.

✅ Versatile application: The machine can be adapted to different sizes and types of boards, whether they are joined internally or externally, providing a flexible solution.

✅Efficient production: Increase productivity with equipment that performs welding tasks at high speeds and with high efficiency. You will see a significant increase in welding speed, creating more business opportunities.

✅ INTELLIGENT CONTROL: Advanced control system and technology ensure the stability and reliability of the welding process. Intelligent control system makes operation easy.

✅ Adaptation to a wide range of materials: Whether it is metal or synthetic materials, the equipment is able to cope with the welding needs of different materials, providing you with a full range of manufacturing solutions.

✅ Safety: The equipment is usually equipped with advanced safety systems to safeguard the operator during the welding process. Sensors and automatic shutdown mechanisms provide additional safety protection.

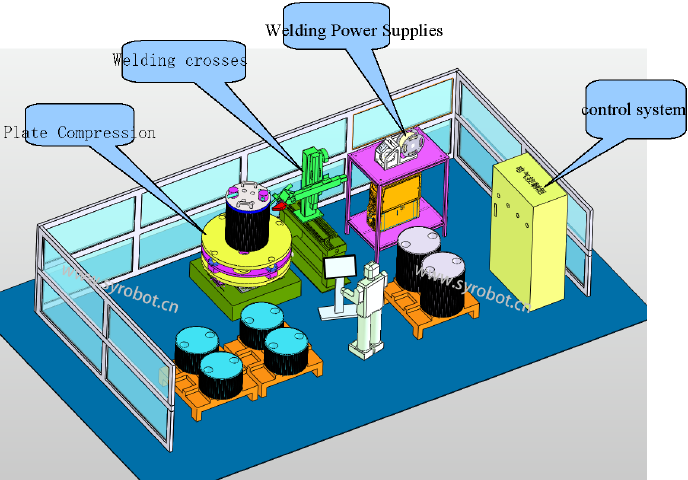

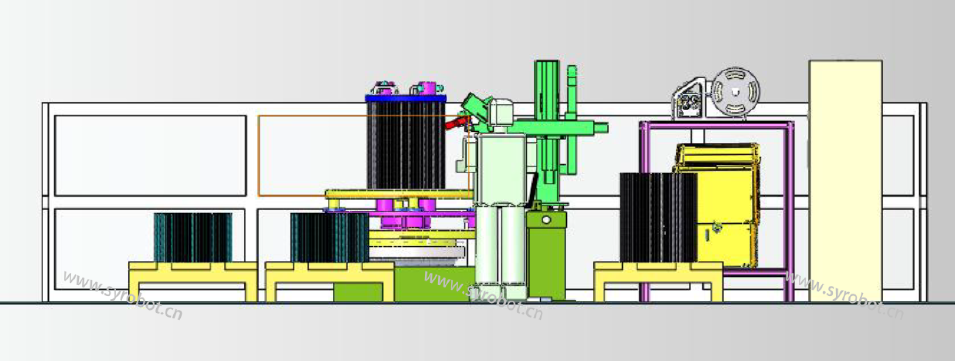

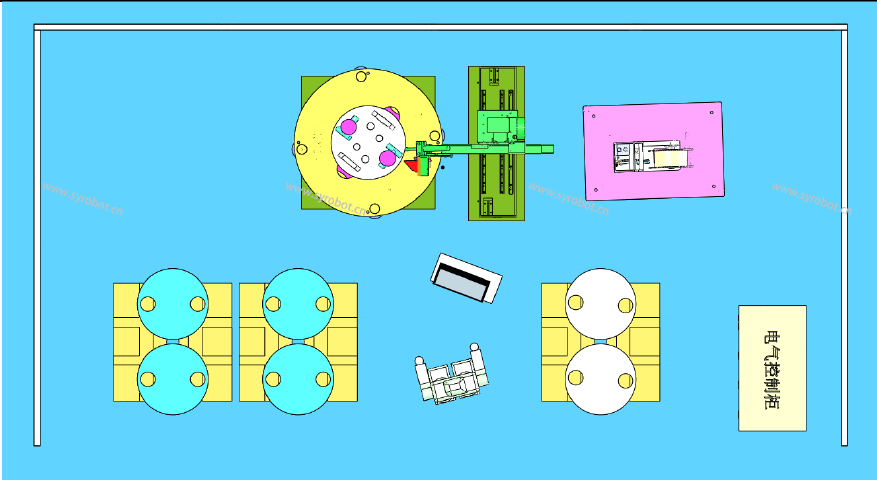

三、Equipment 3D design drawings

This equipment can be customized and manufactured according to customer requirements.

Vertical cylindrical welding machine

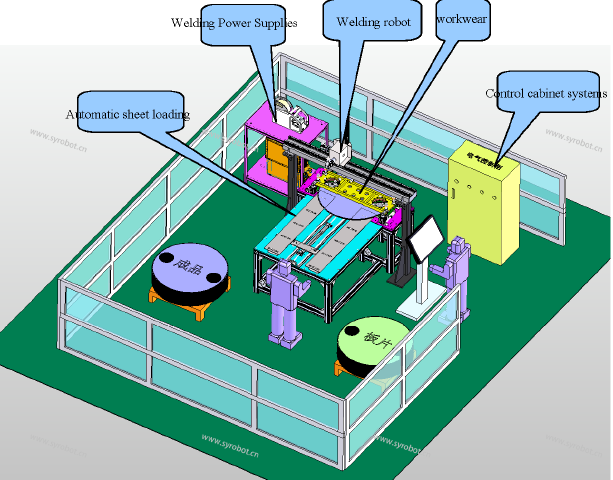

1.Equipment Layout:

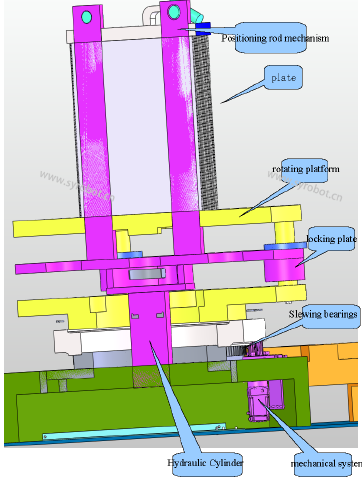

2.Hydraulic compression mechanism:

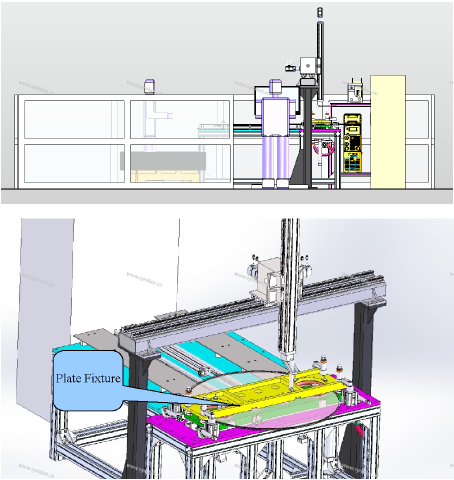

Vertical welding machine for internal cylinders

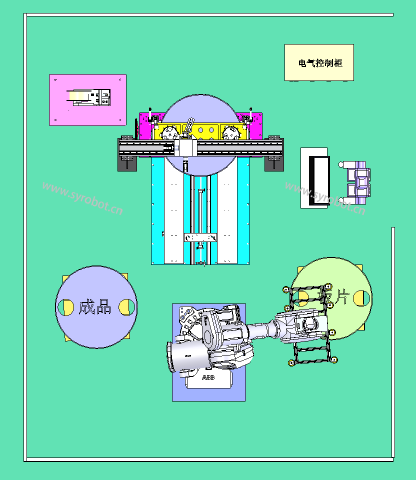

1.Schematic diagram of main equipment composition and processing technology flow:

四、assembly process

Vertical cylindrical welding machine:

Process 1: Workers place the plate onto the automatic rotary pressing table; after the plate is finished, clarify the neatness, and then put the positioning pin into the positioning bar.

Process 2: Manually start the hydraulic cylinder of the pressing mechanism to press the plate, and then start the welding robot;

Process 3: The person in the control system to select the corresponding plate type, confirm the welding parameters, and adjust the position of the gun, and then press the start button;

Process 4: After completing one round of welding, the next round of welding will be carried out automatically, pointing to the completion of welding. After the welding is finished, put away the pressing mechanism, move the locating pin out of the locating bar, and then in lifting away the workpiece; complete all the welding of a workpiece.

Process 5: Perform Process 1 through Process 4 until the workpiece is completely welded or until welding is stopped;

Vertical welding machine for internal cylinders:

Process 1: Workers place the boards into the designated position of the automatic loading and unloading system according to the regulations, and then press the start button;

Process 2: The automatic loading and unloading system pushes the sheet into the sheet fixture, then automatically positions and tightens the sheet;

Process 3: The welding robot is started and the plate is welded;

Process 4: After the welding is completed, the automatic loading and unloading system will take out the welded boards, and then the workers will replace the new boards;

Process 5: Perform Process 1 through Process 4 until the end of plate welding;

五、case (law)

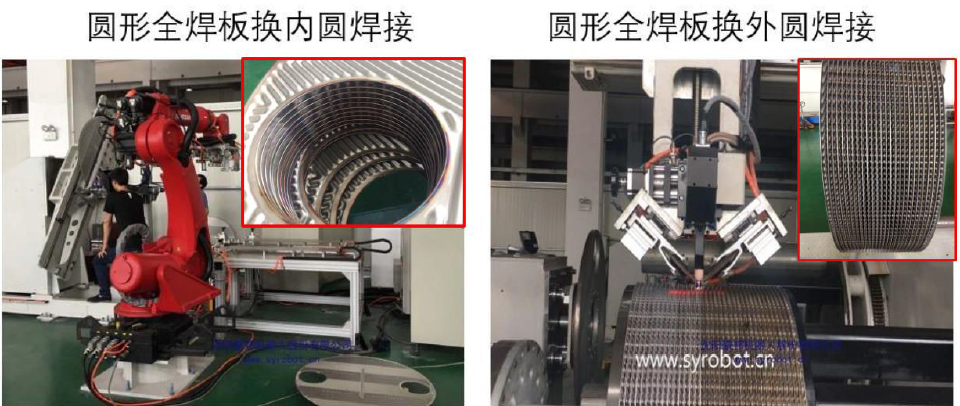

Circular all-welded plates for internal welding Circular all-welded plate exchange cylindrical welding